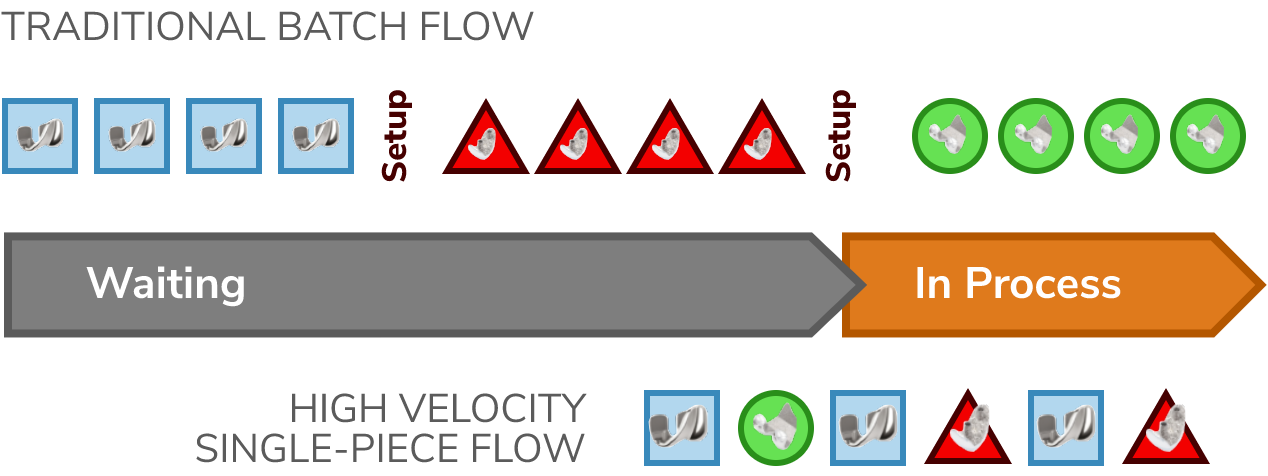

Mach Medical is revolutionizing the orthopedic supply chain with a contract manufacturing operation that builds the highest quality joint replacement implants for OEMs in response to an individual patient’s pre-operative surgical plan and supplies that product in time for their surgery. Facilitating this is our High Velocity Single-Piece Flow Manufacturing approach and end-to-end supply chain management services. Of course, our highly efficient manufacturing platform is suitable for batch manufacturing as well.

High Velocity Manufacturing

Machine setup time driving larger lot sizes for efficiency and cost

Zero Setup time and automation allows cost-effective manufacturing with lot sizes as low as one

High Velocity Manufacturing reduces overall OEM inventory requirements by up to 85%

High Velocity Engineering Transfer

Our High Velocity Engineering Transfer process, when combined with High Velocity Manufacturing and its capability of building just the implants needed for a given surgery and avoiding massive inventory builds for launch, can reduce time-to-market by 1-2 years.